Definition and principles of Kaizen PDF

Introduction to the Kaizen Philosophy

Kaizen is defined as continuous improvement. It is a philosophy of continuous improvement involving small changes throughout all areas of an organization. When applied to the workplace Kaizen involves all employees – from executives to laborers, and everyone in between.

The Kaizen philosophy has been implemented in organizations around the world. It has been used as a way to improve production efficiency as well as improve employee morale and safety

Kaizen – The Definition

Kaizen (Ky ‘ zen) is a Japanese term that means continuous improvement, taken from the words ‘Kai’, which means continuous and ‘zen’ which means improvement. Some translate ‘Kai’ to mean change and ‘zen’ to mean good, or for the better.

If you are aware of the Kaizen philosophy and strive to implement it, not a day should go by without some kind of improvement being made somewhere in the company.

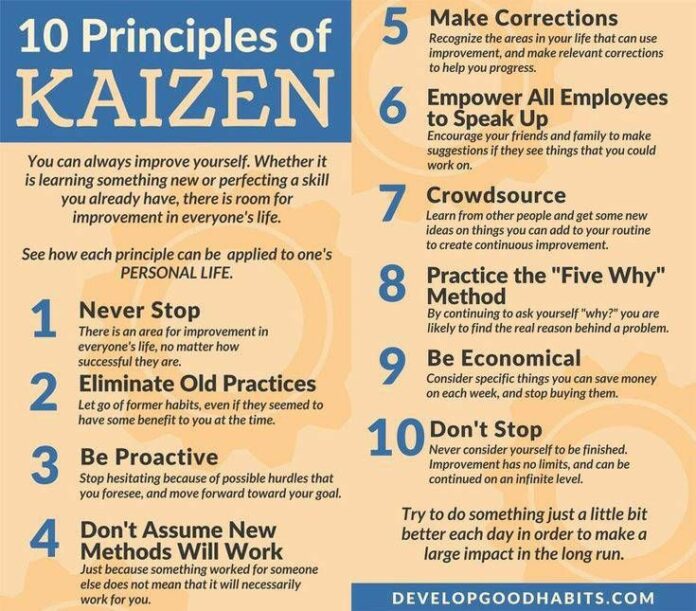

10 Principles of kaizen

It comprises of 10 simple principles, all of which are to be followed simultaneously and continuously. It is a lifestyle change for an organization that is promised to provide visible results:

- Embrace new ideas and let go of rigidity

- Be accountable, and avoid the blame-cycle

- Stay positive, and never take, or give no for an answer

- Aim for small improvements rather than perfection

- Correct mistakes as soon as they are found

- Empower every team member to provide solutions to problems

- Delve deeper into problems in order to ascertain their root cause

- Seek the wisdom of 10 rather than the expertise of 1

- Trust data over opinions

- Kaizen has no destination

kaizen continuous improvement

In any business, management creates standards that employees must follow to perform the job. In a Kaizen environment, maintaining and improving standards is one of the main goals of management. When standards are improved, there should be an observable improvement in the output of a process or procedure.

The objective is to maintain that improvement and then to improve upon it again. This is an unending cycle. If you do not maintain the standard, the desired output is bound to slip back, giving it the “two steps forward, one step back” effect. Lasting improvement is achieved only when people work to higher standards. For this reason, maintenance and improvement go hand-in-hand.

Generally speaking, the higher up the manager is, the more they should be concerned with improvement. At the bottom level, an unskilled laborer may spend the day simply following instructions. However as he becomes better at his job, he begins to think about ways to improve or make his job easier. In doing this, he finds ways to make his work more efficient, thus adding to overall improvement within the company.

The value of the improvement is obvious. In business, whenever improvements are made, they generally result in better safety, quality, and productivity.

Improvement is a process

The process starts with recognizing a need. The need becomes apparent when you recognize a problem. Kaizen puts an emphasis on problem awareness and will lead to the identification of problems.

Kaizen Is Problem Solving

Where there are no problems, there is no potential for improvement. When a problem is identified, Kaizen is working. The real issue is that the people who create the problem are often not those who are directly inconvenienced by it. Another issue is that in day-to-day management, the first instinct is to hide or ignore the problem rather than correct it.

This happens because a problem is …. well, a problem! By nature, nobody wants to be accused of having created a problem. However, when you think Kaizen, each problem can be turned into a valuable opportunity for improvement.

According to Kaizen philosophy, when a problem is identified, that problem must be solved. Once a problem is solved, that typically results in the need to change standards, which then replaces a previously set standard. A new, higher standard is created and is the basis for the continual improvement that results from Kaizen.

Kaizen Methodology Tutorial for Continuous Process Improvement | Process Improvement using Kaizen

This “Kaizen Tutorial for Beginners” video from Invensis Learning brings to you a detailed explanation of an approach to continuous, incremental improvement – Kaizen. It also explains the history of Kaizen and how kaizen works to achieve regular, incremental improvements.

Areas Covered:

- What is Kaizen?

- History of Kaizen

- Dual Nature of Kaizen

- Main Features of Kaizen

- Principles of Kaizen

- Best Practices of Kaizen

- Types of Kaizen

- Examples of Kaizen

- How Kaizen Works?

- Main Aspects of Kaizen

- Phases of Kaizen

- Pillars of Kaizen

- Kaizen Events